Project of the month

"Replacing Excel as the production planning tool "

Initial situation

- An international manufacturer of retail environments employs a variety of Excel spreadsheets to plan and control the order processing and production

- A continuous flow of information from order processing through engineering and work preparation to order execution and on-site installation is not available.

- The usage of planning and control functions within the existing ERP system is very limited

- No transparency to order backlog, production progress and key production data is available

Improvements achieved in this project

- Eliminated the need for staff and work center related Excel spreadsheets for planning and controlling of production orders.

- Enabled high transparency of production progress, online and in real time

- Plan, manage, and control production orders are now based on actual process data instead of relying on gut feelings of staff members

Approach

- Preparation of a current state analysis of order processing processes from receipt of order to delivery.

- Development of an optimized continuous order processing process with emphasis on:

- Implementation of central production planning and scheduling position with the following responsibilities:

- Planning and management of order processing from engineering to installation.

- Coordination with area supervisors to prevent impending delays

- Systematic production capacity planning utilizing ERP-system functionality

- Leading the daily/weekly planning meeting

- Preparation of Make-or-Buy decisions

- Determination of key performance indicators for internal supplier reliability, production cost and productivity.

- Analysis, monitoring and ongoing updating of key performance indicators (KPIs)

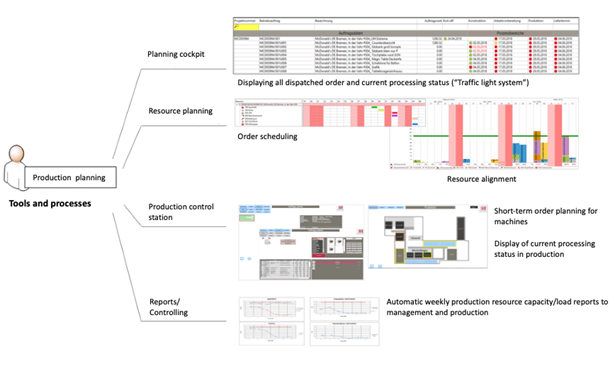

- Extension of ERP-system modules

- Implementation of a planning cockpit overviewing all production orders, displaying the processes involved and the specific processing states.

- Implementation of a resource planning module for engineering, work preparation and production

- Production control station with real time production progress data

- Automatic generation and publication of key performance indicators utilizing the ERP-system

- Provide support and assistance from analysis, conceptualization to job site implementation.

- Audit the new order processing processes once implemented.