Project of the Month

"Expanding Wooden Modular Construction“

A Strategic Manufacturing Concept

KEY FIGURES

- Duration of Development: Less than three weeks

INITIAL SITUATION

A prominent construction company has identified an opportunity to expand its expertise in wooden modular construction, specifically for serial renovations and new builds. In pursuit of this goal, the company is contemplating the establishment of a new industrial manufacturing facility dedicated to producing wall elements, which are currently manufactured at multiple locations.

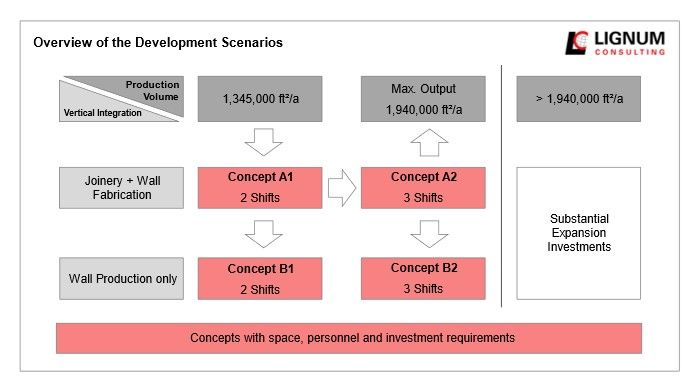

To support this initiative, Lignum Consulting has been commissioned to develop a suitable "manufacturing concept." This concept will serve as a foundational document for making informed investment decisions and will outline the requirements necessary for the search for an appropriate rental building. A critical aspect of this analysis involves exploring various development scenarios, considering production volumes and the depth of manufacturing capabilities, and particularly the trade-offs between outsourcing components and performing in-house processing.

APPROACH

The project commenced with a detailed assessment of the company’s operational framework. The following steps were taken to outline the necessary capacities and infrastructure for the new facility:

- Establishment of Quantity Framework: Define the required capacities for processing, wall manufacturing, and storage to ensure that production demands are met efficiently.

- Current vs. Target Process Evaluation: Conduct a comprehensive analysis of the existing processes for renovation and new construction products, identifying gaps and opportunities for improvement.

- Identification of Product-Related Restrictions: Evaluate limitations hindering higher automation levels and identify potential savings through standardization practices.

- Automation Level Assessment: Determine the appropriate degree of automation for production and logistics to enhance operational efficiency.

- Supplier Evaluation: Assess various manufacturing and machinery concepts from potential suppliers to identify the most suitable options for the company’s needs.

- Facility Layout Design: Develop a block layout of the manufacturing facility, including the exterior space, to optimize workflow and accessibility.

- Investment, Space, and Staffing Requirements: Analyze the investment costs, spatial needs, and workforce requirements associated with various development scenarios.

- Minimum Facility Requirements: Define the essential criteria for the rental facility, including infrastructure and amenities needed to support operations effectively.

KUNDENNUTZEN / ERGEBNISSE

As a result of the comprehensive analysis and insights derived from the project, several key findings emerged:

- Based on the processing capacities developed over recent years and optimistic market forecasts, the initial phase recommended against pursuing in-house processing capabilities.

- The new facility will initially concentrate on efficient element manufacturing while reserving adequate space for future backward integration, allowing for flexibility as the market evolves.

- To facilitate increased production volumes without necessitating additional machinery investments, a third operational shift will be implemented, optimizing the use of existing resources.

- The key figures and data generated throughout this process will enable a subsequent OPEX analysis, allowing the client to evaluate the proposed business case's overall profitability and viability.

The project's overarching goal is to maintain operational heights as low as necessary while maximizing strategic potential. Drawing on extensive industry experience, we at Lignum Consulting work as a strategic sparring partner, offering neutral and independent technical expertise to guide our clients through significant operations transitions.